Vacuum coating technology, also known as physical vapor deposition (PVD), refers to the vacuum condition, the use of a variety of physical methods, will be vaporized into atoms, molecules or ionized into ions, directly deposited on the surface of the matrix method, mainly including vacuum evaporation, sputtering coating, ion coating and so on.

TG series ion coating machine are using the ion plating technology, ion plating technology is in vacuum evaporation and vacuum sputtering coating technology developed on the basis of a new coating technology, the coating technology due to the substrate during the deposition of membrane by high-energy ion bombardment and very clean all the time, so it is compared with the evaporation coating and sputtering coating, Has a number of advantages.

The deposition principle of ion plating technology can be simply described as follows:

The vacuum system vacuumizes the coating vacuum chamber. When the coating vacuum chamber is pumped to the vacuum degree of about 10-3Pa, argon gas is injected into the coating chamber through the charging system to stabilize the internal pressure at 10-1Pa. At this time, when the substrate relative evaporation source plus negative high pressure. A plasma zone is formed between the substrate and the evaporation source. Because the substrate is surrounded by plasma at negative high pressure, it is constantly impacted by ions in plasma, so it can effectively eliminate the gas and dirt absorbed on the substrate surface. The surface of the film is always kept clean during the film forming process. At the same time, the arc evaporation source vaporizes the film into a gaseous state through low-voltage arc discharge. Due to the collision of positive ions and electrons in plasma, some of the film vapor particles are ionized into positive ions, which are attracted to film on the substrate under the action of negative high-voltage electric field.

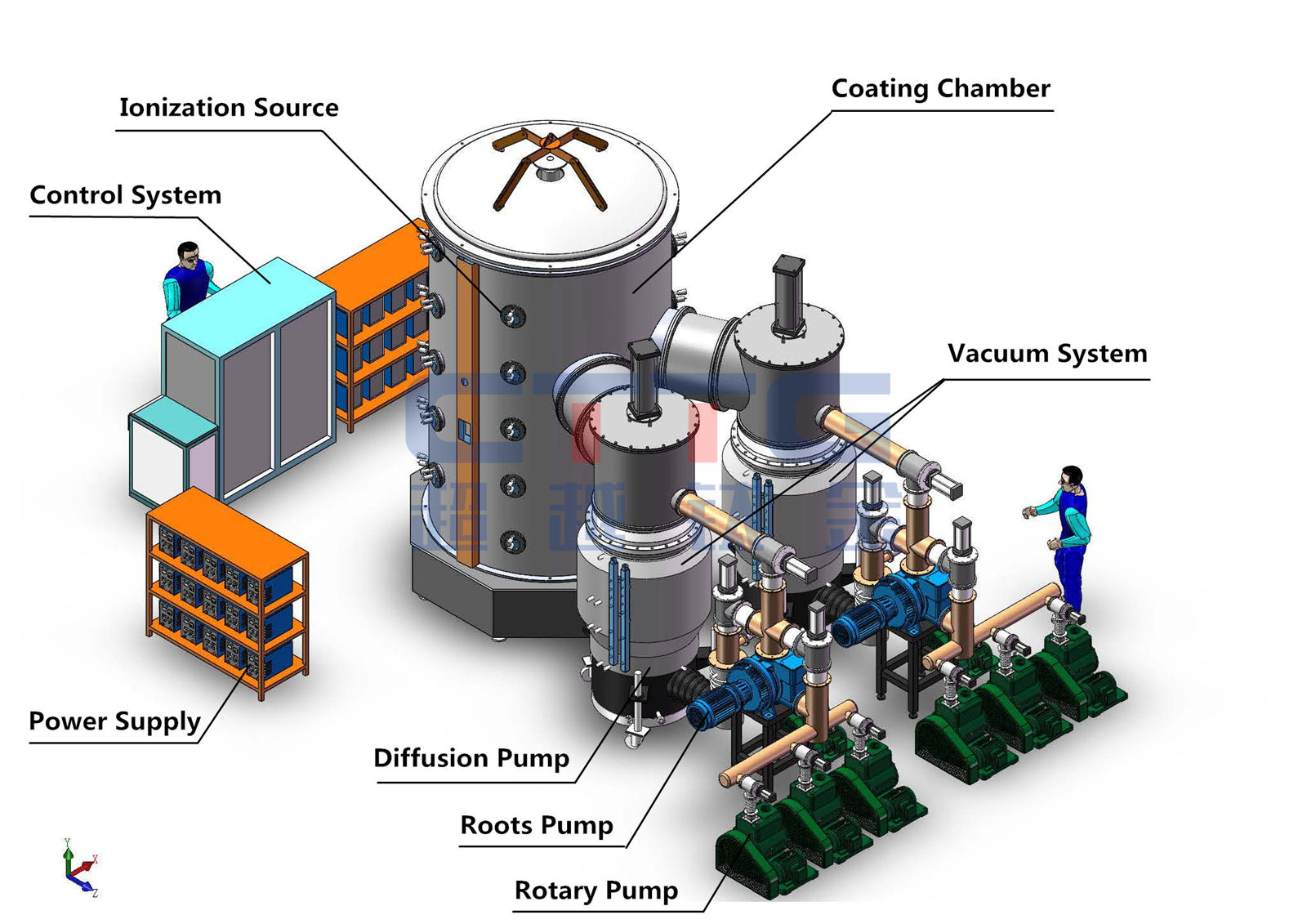

The basic components of arc ion plating include vacuum coating chamber, cathode target arc source, plated workpiece, negative bias power supply, vacuum system, as shown in the figure. The cathode arc evaporation source is the core of arc ion plating, and the metal plasma generated by it automatically maintains the arc discharge between the cathode and the coating chamber. The current density of the spot is very high, reaching 105-107A/cm2, and the voltage is about 20V. Because the energy density of micro-arc is very large, the arc spot can emit metal vapor flow at a speed of 108m/s. The cathode target itself is both a source of evaporation and ionization.